According to the dossier, the Australian Government has identified silicon as a critical mineral, given its current supply chain risks and its importance to new economy technologies such as solar cells, semiconductors or chips, optical fibres, aluminum alloys, and some types of energy storage devices.

Silicon is abundant in Australia in the form of quartz, but the process of smelting quartz to silicon, then to high-purity silicon has not been sufficiently developed.

“Australia already has the highest per capita deployment of rooftop solar in the world, and there are several mega-projects in the solar development pipeline,” Chris Vernon, CSIRO senior principal research scientist, said. “But one of the greatest risks to Australia’s solar ambitions and energy future is our reliance on overseas supply chains for solar cell technology.”

The report notes that increasing the in-country production of silicon is the first step for Australia to develop its own capability and capacity in the solar cell supply chain.

“Demand for solar power and current supply chain dynamics means Australia must grasp the opportunity now,” the document states. “Between 2021 and 2050, solar PV’s contribution to the energy mix in Australia is expected to increase from 12% to approximately 50%, while according to the International Renewable Energy Agency, estimated annual global solar power generation capacity must increase more than five-fold by 2030, and 14-fold by 2050 to stay on track for net-zero targets.”

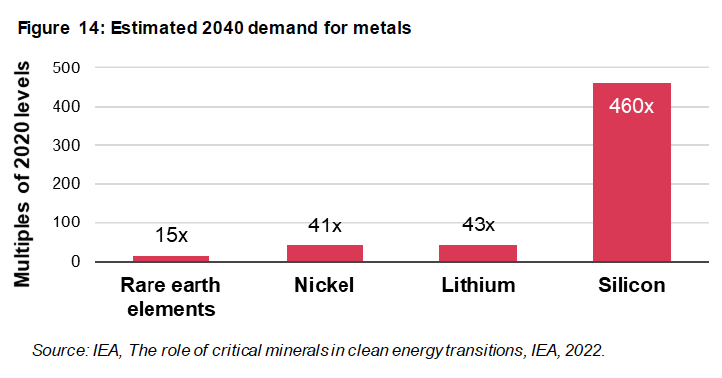

The PwC analysis says that to keep pace with these solar capacity forecasts, annual global production of silicon and its purified form – polysilicon – will have to materially increase.

At present, around 70% of silicon is produced in China, while China also dominates the production of polysilicon. The conversion of polysilicon to solar cells is even more concentrated, with China accounting for between 75% and 97% of these stages of production.

From quartz mining to recycling

The Australian Silicon Action Plan suggests that it is possible for Australia to grow its share in the silicon market by developing a fully integrated silicon and solar cell supply chain, from quartz mining through to manufacturing, end-of-life processes, and recycling to support and de-risk the overall solar supply chain. To this end, the plan proposes three horizons:

- Horizon one – actions that can commence immediately as first steps for developing an integrated silicon and solar cell supply chain. These include identifying potential locations for new smelting facilities, integrating renewable power into smelting processes, and research funding into next-generation processes and technologies.

- Horizon two – actions focused on expanding Australia’s supply chain activity, such as developing more complex supply chain steps for manufacturing components for solar cells.

- Horizon three – actions that will lead to an integrated, low-carbon and circular solar cell supply chain in Australia, such as supporting polysilicon production and focusing R&D efforts on developing and scaling emerging and future technologies.

“Australia has enormous potential when it comes to supplying solar power for its own and also the region’s energy needs, but our current reliance on concentrated silicon and solar cell supply chains poses risks to Australia’s energy independence,” Vernon said. “The Australian Silicon Action Plan suggests a pathway for the creation of an industry that has the potential to provide employment and reskilling opportunities, the delivery of significant economic benefits that come from adding value to Australia’s mineral endowment, development of new industries in regional Australia with the world’s best ESG standards, all while improving Australia’s energy security and independence.”